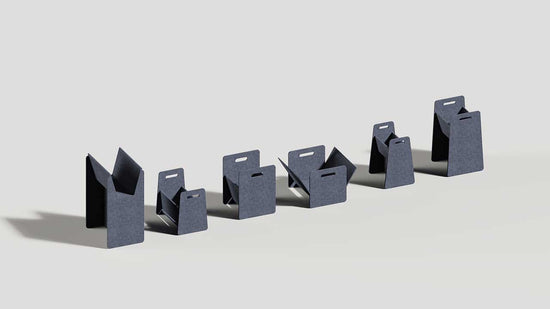

Form Shaped Parts

We are one of the leading specialists for molded parts using molded fleece, thermoplastics, organic granulates and wood. The molded parts are manufactured thermoplastically and then further processed using a wide variety of cutting and post-processing methods.

Form Shaped Parts

-

Formfleece (Compression Molded)

Compression MoldingNonwoven materials can be transformed into 3D shaped parts using compression molding. A formfleece has similar rigidity and strength as a conventional plastic molded part, but does not lose its fleece structure and felt-like surface. Molded parts made of fleece are therefore very well suited for acoustic applications or as a substitute for upholstered elements. The production of nonwovens makes it possible to use materials from recycled or renewable sources so that products made from them are sustainable.

Polyester Formfleece | Natural Fiber Formfleece | Recycled Textiles Formfleece

-

Formed parts made of plastics (Thermoforming)

ThermoformingFormed parts made of plastic using thermoforming are formed from plate materials in a vacuum. The molded parts are often suitable for technical applications with precise requirements in terms of temperature, humidity resistance and impact strength. The process allows a wide variety of design characteristics such as high gloss or matte, a wide variety of colors, textures or foils. The materials are also very suitable for a recycling loop, as mostly mono-material is used that is very easy to recycle.

-

Form parts made of bio-granulates (Injection Molding)

Bio-Injection MoldingOrganic plastic granulates can be transformed into molded parts using injection molding. These bio-plastics have very similar properties to conventional, oil-based plastics. Visually, they can retain their natural look or be modeled after other plastics with organic colors. The materials are of bio-based origin and thus have properties such as biodegradability, but are also recyclable.

-

Molded parts made of wood (Wood Processing)

WoodworkingWe can process wood using a wide variety of woodworking techniques. This includes pressing wood, creating wood veneers, milling and sawing, and other steps. Wood is naturally renewable and can be processed into different looks or laminated with other materials. We only use sustainable types of wood and check them regularly.

Our Expertise

For more than 20 years we have been manufacturing products for the furniture industry, automotive, funeral, professional audio and medical technology. Our expertise here is based on experience with bio-based and recycling materials and processing these. We manufacture in small series as well as large series. If you have any questions about our competencies, our production or a possible cooperation, please do not hesitate to contact us. We would be happy to advise you!